Industrial Racking

Al Khalaf Co. is one of the leading companies in the storage systems market specializing in the design, manufacturing, sales and services of metal racking, automated warehouses and other storage solutions.

Our Racking Division is established to provide support and advice to organizations requiring a complete range of storage products to be either supplied or installed.

Types of Racking

Type of Racking Systems include:

- Selective Pallet Racking

- Drive-in Racking

- Drive-through Racking

- Mobile Racks

- Cantilever Racks

- Long Span Storage Systems

- Mezzanine

Why industries choose Racking:

Industrial racking transforms empty vertical space into high-capacity, organised storage that works smarter—not harder. It keeps products easy to reach, speeds up warehouse operations, and boosts safety across the floor. Businesses choose racking because it delivers maximum storage, clean organisation, and unbeatable efficiency without expanding their footprint.

Selective racking is the most widely used warehouse storage system that provides direct access to every pallet, making inventory management simple and efficient. It is ideal for operations with a wide variety of SKUs and frequent stock rotation

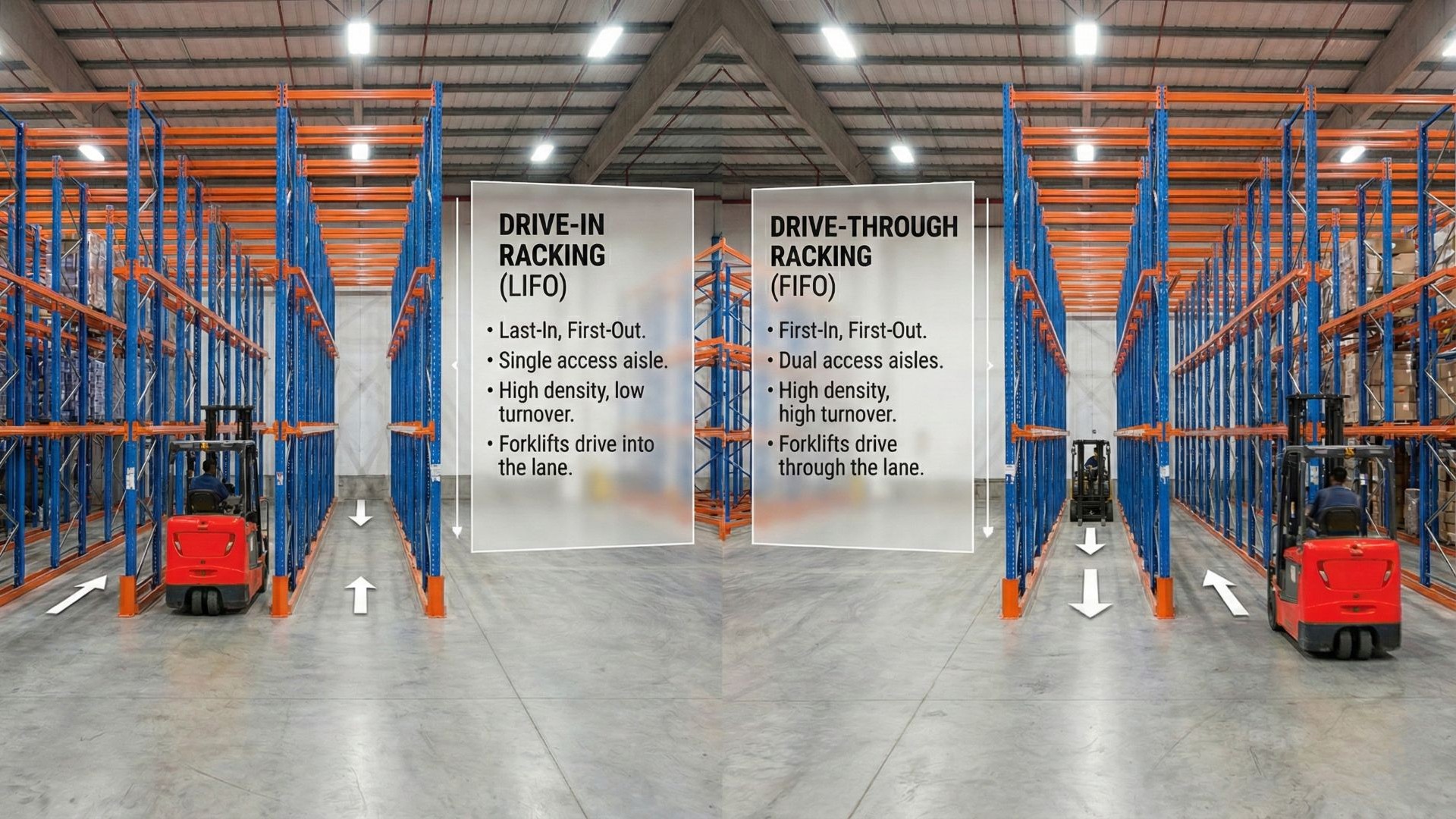

Drive-in and Drive-through racking are high-density storage systems designed to maximize warehouse space by minimizing aisle requirements.

Drive-in racking: Drive-in racking allows forklifts to enter the rack structure to store pallets, maximizing space by reducing aisles. It operates on a last-in, first-out (LIFO) basis and is ideal for high-density storage of similar products.

Drive-through racking: Drive-through racking is similar in design but allows access from both ends of the rack. It follows a first-in, first-out (FIFO) system, making it suitable for goods with expiry dates or high stock rotation.

Mezzanine racking is typically used to store light to medium-weight materials such as cartons, boxes, spare parts, tools, documents, retail goods, and small components. It is especially suited for manual picking items, fast-moving SKUs, and organized inventory rather than heavy pallets.

Cantilever racking is designed for storing long, bulky, or irregularly shaped items such as pipes, timber, steel bars, and panels. It features horizontal arms extending from vertical columns, allowing easy loading and unloading without front obstructions. This system is ideal for warehouses handling oversized materials and varying load lengths.